Ticking is a single cloth, of either medium or heavy weight, and is composed of single cotton yarns from 1-14s to 1-22s in warp and filling or combination of both, such as 18s warp and 20 filling. It is a good, stout cloth, having fine wearing qualities, and is used principally for making bed ticks and pillow and bolster cases. It is generally made with what is known as a bed-tick weave or twill, either right or left handed 45s twill broken or herring-bone. It can be woven in any power loom, but is best adapted to and most always woven in the plain single box looms.

Ticking- belongs to the family of stiff, hard face cotton fabrics. This feature is created by using twill weaves (warp effect), and these weaves permit of the use of a imore than ordinary high warp texture. For Instance, take 3/1 twill: In this weave there are interlacings of each warp thread in every four picks of filling, thus allowing ends to lie closely together—hence permitting an increase in ends per inch. These goods are usually made in two colored warp patterns—dark blue and white, red and white. WHITE FILLING IS USED IN ALL CASES. Fast colors should be used in warp as bed-ticks are sometimes ripped open and the cloth washed. In this case the light and air renew the coloring on the yarns.

Ticking is woven with from 60 to 84 ends and picks per inch in the loom, according to grade required. The greater the number of warp threads the stouter the fabric in proportion to counts of yarns used. To finish these goods, they are brushed and sheared to remove all lumps and foreign substances from the face of the cloth. Then the cloth is sized and calendered, which acts in the same manner as a hot press, after which the cloth is lapped or rolled into bolts, then stitched, and is ready to pack and ship.

|

The speed of the fan of the opener should be 1,100 revolutions per minute. The speed of the beater (of a two-bladed, rigid type) should be at least 15,000 revolutions per minute, and the weight of lap about 40 pounds or 20 ounces in weight per yard. The lap is put up at the breaker and doubled four into one and delivered so as to weigh 14% ounces per yard or about 39 pounds for the whole lap. The SPEED OF THE BEATER on this machine should be 1,450 revolutions per minute. The beats per inch that the cotton would receive would be about 42. See that all your drafts on the picker are properly regulated so that a lap will be obtained that will not split. Of course, this is not the only reason that makes a lap split, but it is one of the principal ones. Another cause for split laps is found in putting too much waste in the mixing. The lap is then put up at the card which should be provided with coarse wire fillet. The DRAFT OF THE CARD should not exceed 100. The weight of the sliver should be about 65 grains per yard and the production about 1,-000 pounds per week of 60 hours. The cards should be ground at least once every month, having the grinding rollers on for at least a half a day. Of course, grinding means loss of production, but it has to be done; otherwise, bad work will result, and if you keep your wire sharp you will find that you will have less trouble with your cards and a great deal less kicking on account of poor work. THE SETTINGS that should be used for this class of goods have been given in a previous lesson. The card sliver should be put through two processes of drawing, the sliver weighing 75 grains per yard at the finisher-drawing frame. Remember to never draw more than you double. The sliver is passed through the slubber and the hank roving should be about .40. Set the rolls for %-inch stock on this machine as follows: Front to imiddle, 1% inches; middle to back, 2 inches. Two processes of fly frames should be used, the hank roving being made at the first intermediate about 1.40, and at the second from 3 to 3.40. THE SPINNING. This roving is then taken to the spinning room where it is spun into the required count. For 16s the following would be a good equipment for a warp frame: gauge of spindle, three inches; diameter of ring, two inches; length of traverse, seven inches; and for a filling frame: gauge of spindle, 2% inches; diameter of ring, 1% inches, and length of traverse, from 6% to 6% inches, according to twist put in; the more twist the more length of traverse may be used. The production for a spinning frame for 16s, with the speed of front roll 139 revolutions pea- minute, twist 19 and revolutions of spindles 8,300, would be about 3.15 pounds per spindle per week. For a filling frame for 16s, with front roll speed of 159 revolutions per minute, twist, per inch 13, speed of spindles 6,500 revolutions per minute, the production would be about 3.34 pounds per spindle per week.

|

CONSTRUCTION OF TICKING.

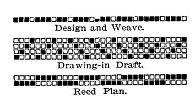

Reed 725—33 inches, 4 ends per dent. l-16s warp, l-20s filling, 74 picks; 12% per cent take-up in weaving; 10 per cent size on warp, 7 per cent size of cloth in finish; 3—herring-bone twill weave; finish equals 31% inches, and includes brushing, shearing, sizing and calendering. Cardinc, and Spinning Particulars. The yarns used in ticking are made in mills of the first division as given im a previous article. The length of the raw stock used varies in different mills according to the grade of ticking to be made, but is generally % to 1% inches in length. This does not mean that raw stock of from % to 1% inches is used in the same mixing, but that the mixing is made up of stock of uniform length. THE MIXINGS for this class of goods are generally made by hand and the bins should be made as large as possible so as to accommodate large mixings. It would be better to have two large bins Instead of one, so that one lot of raw stock could be opened and dried out while feeding the machines from the other bin. On this class of goods comber waste is used in some mills and the cut roving waste is also mixed as has been before stated. An opener and TWO PROCESSES OF PICKING are used and the lap should be made as heavy as possible without, of course, making it so heavy that it wil' bring up the cards and finisher picker. Keep the hopper of the opener as full as possible and you will find that an evener lap will be made.

|

Dyeing Particulars.

Formerly ticking had only blue stripes dyed indigo blue. For some time a variety of colors have been introduced, and now many colors are used, some with narrow stripes mixed with broad stripes, having from three to five or more different colors in the same pattern.

BLUE. Dyed with indigo or one of the sul-p!hur blues. Eight per cent pyrogene Indigo; 8 per cent sulphide sodium; 3 per cent soda ash; 20 per cent common salt. This color can be aftertreated with 1% per cent chrome; 1% per cent capper sulphate; 3 per cent acetic acid, 125 degrees F.

ECRU. One-quarter per cent tetrazo cutch brown; % per cent tetrazo black N; 2 per cent soda; 20 per cent Glauber's salt LIGHT SLATE. Three-fourths per cent Thion black B; 1% per cent sal soda; 1 per cent sulphide soda; 10 per cent Glauber's salt.

RED. Three per cent tetrazo red, 4 B; 2 per cent sal soda; 20 per cent Glauber's salt.

DARK BROWN. One and one-quarter per cent Thion black B; 5 per cent Thion brown G; 3 per cent sal soda; 6 per cent sulphide soda; 20 per cent Glauber's salt.

LIGHT BRONZE. One-quarter per cent tetrazo chlorine yellow G G; 14 per cent tetrazo black N; Y4, per cent tetrazo brown R; 1 per cent sal soda; 20 per cent Glauber's salt.

DRAB, One-eighth per cent benzo fast black; % per cent chloramine yellow M; 1-1G per cent benzo fast red G L.

LIGHT OLIVE. One-half per cent benzo dark green G G; % per cent chrysophenine.

DARK OLIVE. Four per cent benzo dark green G G; 2 per cent chrysophenine. The above three colors are each dyed with 20 per cent Glauber's salt and 2 per cent sal soda.

DARK SLATE. Two and one-quarter per cent benzo fast black; % per cent benzo fast blue B N; 2 per cent sal soda; 20 per cent Glauber's salt.

WINE. Four per cent benzo fast scarlet 8 B S; 1 per cent benzo fast violet R; 2 per cent sal soda; 20 per cent Glauber's salt. LIGHT FAWN. One-half per cent diamine brown M; % per cent diamine brown 3 G; 2 per cent sal soda; 20 per cent Glauber's salt.

STEEL. One-half per cent diamine steel blue L; % per cent diamine black B H; % per cent diamine fast yellow B; 2 per cent saltl soda; 20 per cent Glauber's salt. |