Bourrette is a light weight, single cloth fabric, weighing from 4% to 6 ounces, composed of two-ply cotton warp, and either wool, merino or a combination of cotton and wool shoddy Ailing. Both the warp and the filling have an occasional end or pick of fancy bourrette or nub yarn added for effect; hence the name. In appearance bourrette cloth is a semi-rough-faced woolen fabric, having small fancy colored lumps on the yarn, scattered throughout, the goods in accordance with the effect desired. The cloth when finished is used principally in the manufacture of ladies' fall suitings.

|

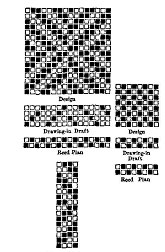

THE WEAVE Is usually a plain weave or a mixed twill effect, such as can be produced from the regular —- 45 degrees twill, viz.: diamond or entwining twill weaves. These weaves, in connection with certain warp and filling patterns, such as 1 black, 1 fancy twist or 2 black, 2 fancy twist, create very elaborate styles, as this color arrangement serves to hide the rigid outline of the design, and thus has a tendency to complicate the general appearance of the weave used in the fabric. The fancy effects in twist that can be adapted to this line are made by twisting the following colors together:

Black and white. Black and light blue. Black and Iig-ht green. Black and old gold. Black and Ted. Black and light brown. These twist yarns serve the purpose of brightening up the general appearance of the goods. Bourrette cloth can be woven in any power loom, excepting those styles wherein a single pick of the fancy yarn is introduced in the filling, in which case the Knowlea 4x4 pick and pick dobby loom is very serviceable.

|

TO FINISH THIS FABRIC

The goods are taken from the loom and measured.after which they are brushed then scoured iu a solution of soap and cold water, then tentered and dried and pressed. The bourrette yarn is made by twisting two cotton threads and a worsted thread together, the worsted being allowed to deliver more quickly than the cotton threads, at regular intervals. The excess which is delivered is twisted around the cotton threads in the one place, thereby forming a lump on the twisted yarn, as the worsted yarn is run at a varied speed, and is not regularly distributed around the cotton threads.

|

Carding and Spinning Particulars.

In the class of goods under description it will be noticed that there is a very small percentage of cotton contained in its make up. If the cotton yarn that this class of goods contains was made in a cotton mill, the following particulars would be a good foundation on which to base the speeds, weight and processes through which the raw stock would have to pass before being turned out into 2-ply 12s or 2-14s yarn, as the case may be. This class of yarn may be made in the first division of mills, and the cotton would be hand mixed and put in the bins. The mixing should be allowed to dry out as much as possible before using, and a better plan would be to have two large mixing bins so that when one was in use the other one might be filled and the cotton dried. This la not always done, because most picker rooms are pressed for floor space.

|