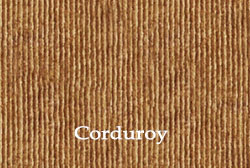

CORDUROY

Corduroy is a narrow, all cotton fabric, the distinguishing feature of which is the perfect half-round regular ribs running warp ways through the cloth. As a fabric, it belongs to the general class of filling pile fabrics and is made of one system of warp and two of filling. The warp must be of good cotton staple to make a fine strong end. The pile filling should be of firsit-class cotton, soft spun, to blend more readily when the ribs are rubbed after being out and brushed. The warp and ground filling is wov- en either 1/1 2/1 or 2/2 twill, the pile pick weaves with either one, two, or three warp end, and floats over from three to 12 warp ends. The length of the float of pile filling depends upon the width of rib or cord desire'd in the fabric. The important point about the pile weave is to cause the pile filling to weave with the same two or three warp threads. This gives us lines of binding and lines of filling floats running warp ways. The velvety ribs or cords, as noted upon the face of a corduroy.are created by first cutting the lines of floats of the pile filling. This operation is performed by hand with a very sharp steel knife, after which the ends of the floats are carefully brushed, and then rubbed together to the proper degree of consistency desired in ribs. Corduroy is woven with from 160 to 500 picks of filling per inch; and is afterward dyed in dark blue, tan, buff, green and olive colors, to be used in making clothing for men. It is also used for upholstery purposes, either in plain solid colors or the plain color has an elaborate floral design printed upon it. These printed patterns are usually in bright colors, such as red, yellow, light green. IN PRINTING, the design is first engraved upon a set of copper rollers. These are set into a regular machine, and as the cloth passes over them, the color being fed to the rollers automatlcally.the design is-placed upon the face of the cloth. It Is woven so as to finish from 27 to 31% Inches, the 27-lnch for clothing and 31%-inoh for upholstery. This fabric requires a loom to be in good condition, as the beating in of such high number of picks per inch of filling is hard on the loom, and also necessitates slow production. It is usually woven on dobby or witch loom, having single or double box. |

Carding and Spinning Particulars. Yarn suitable for making corduroy is made in the second division of mills, given in a previous lesson. The raw stock used should be of a good grade cotton of about 1 inch staple. The mixings should be as large as possible for reasons already stated in previous lessons. One large group of mills, which make this class of goods, use a somewhat, different machine for opening up the raw cotton from that which has been described, and instead of using -an opener after the cotton is put through the bale breaker, it is fed to a machine called THE WILLOW. The cotton is fed into the machine in small lots and the machine pulls it apart and thoroughly airs it. Some overseers claim that this machine treats the cotton to a more thorough airing than when an opener is used. It Is again claimed that, in consequence of this fact, the cotton may be used right from the bale or mixed at this machine. It is an English machine, and while this system is used to some extent in England, it is the general custom to use the opener in this country. Good sliver waste from the cards and drawing frames is used in the mixing, as is also the sliver and lap waste,from the comber room, when the mill is equipped with combers. |

A GOOD WEIGHT for the-lap would be about 38 pounds and the weight per yard 14 ounces. To get the grade of cotton used for this class of cloth clean, about 42 beats should be given to every inch of cotton fed at the back of the finisher picker. In other words, every inch of cotton should be struck 42 times before it is passed by the beater. With the above speed of the beater (1,450) this would be the number of blows that every inch of cotton received. Don't forget that it is very important to remove the fly from underneath the pickers at regular intervals during the day, because, if the fly is allowed to accumulate to any great extent, it might be drawn into the already cleaned cotton passing through the machine, and it is sometimes done as all persons working around cards know, as they have seen at various times large patches of fly on the lap of cotton. This of course requires the card TO DO EXTRA WORK and clean and take out this dirt. It very often results in bringing up the feed roll or the licker-in of the card, if not noticed in time to remove the fly. It will be seen that it is important to keep the picker room clean at all times. It is very important to keep foreign matter, such as nails or pieces of metal, out of the cotton in the picker room, because of the liability of fires in the pickers, these being started by the foreign substance coming in contact with the quick moving beater blades and a spark being struck which ignites the cotton. This is apt to cause a bad fire if not promptly attended to. |

TWO PROCESSES OF PICKERS are used with either a willow or an opener. Cut-roving waste is used and is mixed in at the finisher picker in the way that has been described in a previous lesson. If an opener is used, the speed of the beater should be about 1,000 to 1,100 revolutions per minute, with a speed of the fan about 350 revolutions per minute. The speed of'the beater at the breaker picker should be about 1.500 revolutions per minute, and the speed of the fan about 1,400 revolutions per minute. A good weight for the lap made at the breaker picker is 40 pounds, while a good weight per yard of lap is 16 ounces. At the finisher picker the speed of the beater should be 1,450 revolutions per minute for a two-bladed beater, or 9.50 revolutions per minute for a three-bladed beater. The speed of the fan should be about 1,100 revolutions per minute with either beater. |