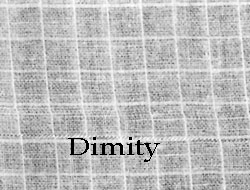

Dimity

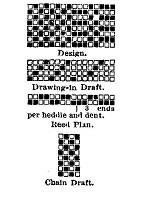

Jacquard scroll and other figures are printed upon the white dimity to create elaborate patterns. Dimity is always woven with a plain weave 2-j, and by printing fancy floral designs upon the white surface of the cloth, that compactness of texture Is retained which the plain weave alone can give. If, for instance-, the floral effect were woven into the cloth, ends and picks remaining the same as for the plain weave, there would be created loose places warpwise of the cloth, due to the warp floats in forming figures. Dimity, being a light-weight fabric composed of very fine yarns, is therefore best adapted to the lightest running looms. A plain or dobby loom would be the most suitable for this fabric; one capable of weaving from two beams, as these are usually woven. Dimity is. made in grades having from 64 ends and picks per inch to 100 and more ends and picks per inch, the count of the yarn varying in accordance with the degree of texture desired. Dimity as a dress fabric has a rather soft feel, and so receives but very slight amount of starch in finishing, which process includes washing, drying and calendering the goods, which are afterward rolled or lapped Into bolts, "each cut or piece constituting a bolt." Each bolt or piece is then folded, the paper bands put on, and the goods are ready to pack and ship.

Carding and Spinning Particulars.

Dimity, or rather the counts of yarn required to make this style of cloth, requires first-class machinery and it is, therefore, made in the third divisionof mills asgiven in aprevious article. The grade and length of staple of the cotton used varies with the weight per yard of the cloth being made and may be composed of 1%-inch. Allen cotton to 2-inch Sea Island cotton. For this lesson we will consider the counts to be 80 and the cotton used to be 1%-inch Sea Island. The mixings should be large and cotton allowed to dry out before being worked.

As Sea Island cotton is comparatively a clean cotton it will consider the counts to be 80 and the cotton used to be 1 5/8-inch Sea Island. The mixings should be large and cotton allowed to dry out before being worked. As Sea Island cotton is comparatively a clean cotton it REQUIRES LESS CLEANING than other cottons, and another reason for putting It through less processes in the picker room is because of its length. If run through too many beaters the cotton Is apt to be filled with neps. For Sea Island cotton of medium to long staple, I. e., from 1% to 2% inches, it is better to use only opener and one process of picking as compared with two processes of picking for other grades of cotton.

Dimity does not yellow easily and can stand up to a lot of wear and tear. Originally Dimity was made of silk or wool but since the 18th century it has been wooven almost exclusively of cotton. it is commonly employed for curtains and bed upholstery.

According to Abraham Rees (The Cyclopedia ,Philadelphia 1810-1824) Dimitry is a kind of cotton cloth originally imported from India and now manufactured in great quantity in various parts of Great Brtitain.