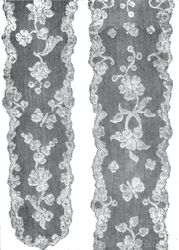

Valenciennes Lace History 2

A very expensive lace No lace was so expensive to make, the reason being the number of bobbins required for fine lace of wide width. While Lille lace-makers could produce from three to five inches a day, those of Valenciennes could not complete more than an inch and a half in he same time. It took ten months, working fifteen hours a day, in finish a pair of men's ruffles, hence the costliness of the lace. |

|

|

After the French Revolution When so many lace-makers fled to Belgium Alost, Ypres, Bruges, Mechlin, and Courtrai became the centres of a new and inferior Valenciennes, each town having a distinctive feature in the ground. These laces are as a rule less close in workmanship, less solid, and cheaper. In Courtrai and Mechlin the grounds are twisted three and a half times; and in Bruges, where the ground has a circular mesh, the bobbins are twisted three times ; that made at Ghent, in East Flanders, is square-meshed, the bobbins being twisted two and a half times. Valenciennes laces made outside the walls of Valenciennes were designated as fausses Valenciennes, whether made in Belgium or in the Department du Nord, at Lille, Bergues, Bailleul, Avesnes, Cassel, and Armentieres. |

Valenciennes Lace from Dieppe At Dieppe, in Normandy, Valenciennes with the square ground was introduced in 1826, by the sisters Fleury and Hubert from the Convent of La Providence at Rouen, and took the place of the old point de Dieppe, which is very like Valenciennes with small round meshes. Of this lace Peuchet says that the designs were inferior, but that an attempt was being made to introduce lighter, less crowded designs. The thread came from Flanders, from Saint Amant. Point do Dieppe requires much fewer bobbins, and whereas Valenciennes can only be made in lengths of eight inches without detaching the lace from the pillow, the Dieppe point is not taken off, but rolled. |

|